full set cement production line

Description

A full set cement production line refers to the complete range of equipment and processes required to manufacture cement from raw materials through to finished product. This production line can be customized based on capacity, type of cement (e.g. OPC, PPC), available raw materials, and energy efficiency goals.

Here’s a breakdown of the main sections and equipment typically included in a full cement production line:

🔧 1. Raw Material Crushing

- Equipment: Jaw Crusher, Hammer Crusher, Impact Crusher

- Function: Crush limestone, clay, and other raw materials into smaller particles.

🧪 2. Raw Material Prehomogenization

- Equipment: Stacker and Reclaimer

- Function: Store and blend raw materials uniformly.

🏭 3. Raw Meal Grinding

- Equipment: Vertical Roller Mill or Ball Mill

- Function: Grind crushed materials into fine raw meal powder for the kiln.

🔥 4. Clinker Production (Pyro-processing)

- Equipment:

- Preheater Tower

- Calciner

- Rotary Kiln

- Cooler

- Function: Heat the raw meal to 1400–1450°C to form clinker (main component of cement).

🧱 5. Clinker Storage

- Equipment: Clinker Silo

- Function: Store hot clinker before final grinding.

⚙️ 6. Cement Grinding

- Equipment: Cement Mill (Vertical or Ball Mill), Separator

- Function: Grind clinker with gypsum and additives to produce cement.

📦 7. Cement Storage & Packing

- Equipment:

- Cement Silos

- Packing Machine (Rotary/Pneumatic)

- Palletizer

- Function: Store and package cement into bags or bulk.

🌿 8. Dust Collection & Environmental Equipment

- Equipment: Bag Filter, Electrostatic Precipitator, Cooling Towers

- Function: Control emissions and ensure clean production.

⚡ 9. Electrical & Automation Systems

- Equipment: MCC Panels, PLC/DCS System, SCADA

- Function: Control and automate the entire line for efficiency and safety.

🏗️ Typical Capacities:

- Small Scale: 100–500 TPD (tons per day)

- Medium Scale: 600–2000 TPD

- Large Scale: 3000–10000+ TPD

📌 Optional Add-ons:

- Waste Heat Recovery Systems

- Alternative Fuel Feeding Systems (for RDF, biomass)

- Grinding Aids & Additive Dosing Systems

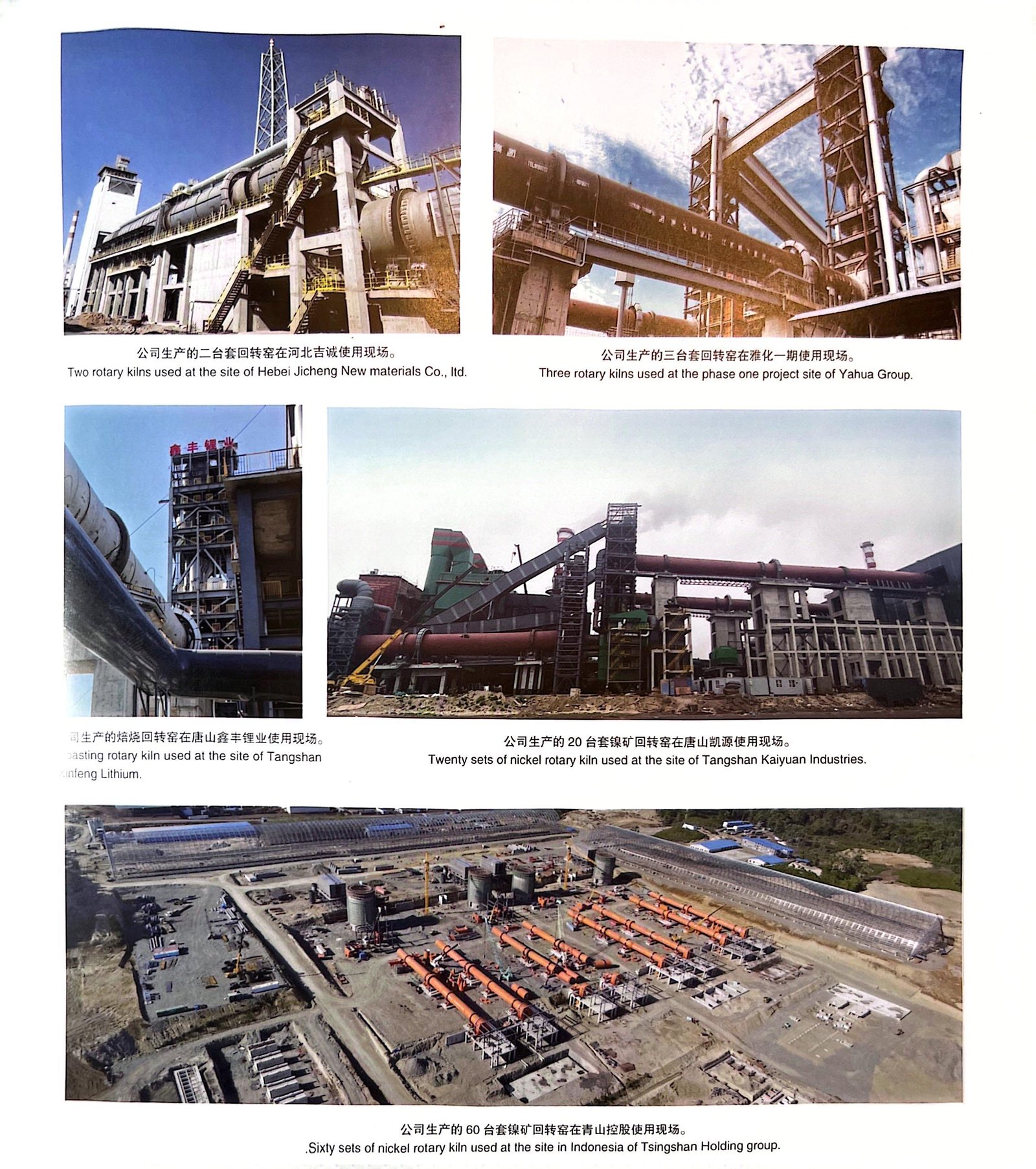

Six 5.0*74m rotary kilns, two PFRM 3.6 raw material vertical mills, and two PFRM6.6 cement vertical mills

Some case:

cement production line:

cement production line:

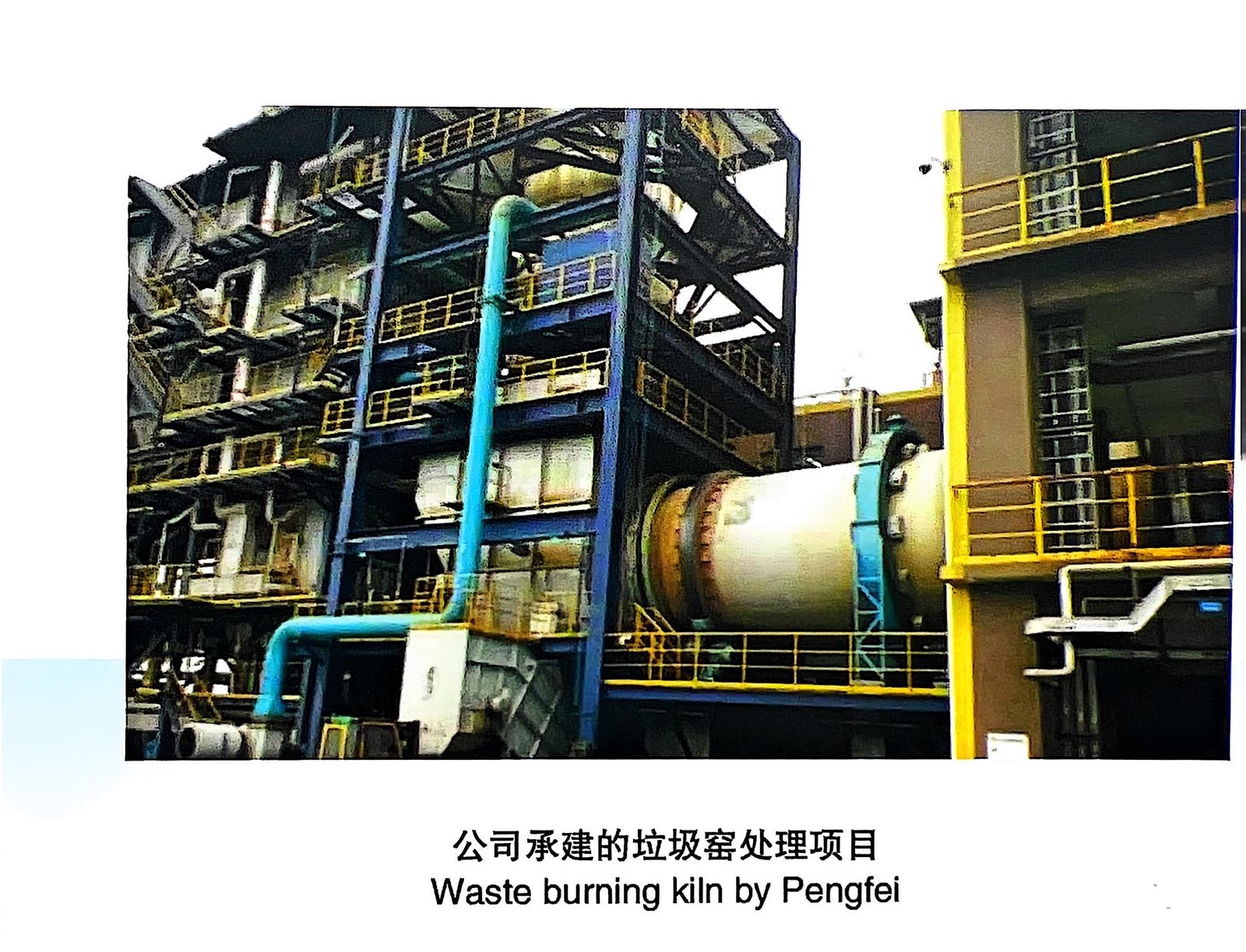

other product—waste burning kiln